As many of you know, a few months ago we unveiled our new navigation tower. Some have raised suspicions that we copied the product, creating unfair competition… so, without setting a precedent, since it’s unusual for a company to show its plans and explain the manufacturing of any product, this time we’ll show you how the tower was designed behind the scenes.

Our work begins around August 2024. Speaking with our friend Pelut, we see that there are no navigation towers at a reasonable price with acceptable quality. The few options we have for our Rally installations limit our quality or force us to work with third parties who are simply making the product more expensive without doing anything. At this point, we decided to design our own tower.

The first challenge we encountered in keeping the product price down was finding a screen that was the right size and shape for this project. After searching and searching, we couldn’t find one that matched our expectations in terms of price and shape, so we decided to use a screen already on the market. For our tests, we’re going to select the Chinese market, and we’re bringing two different models.

We selected the one for a BMW R1250, with a reasonable price of 25 euros.

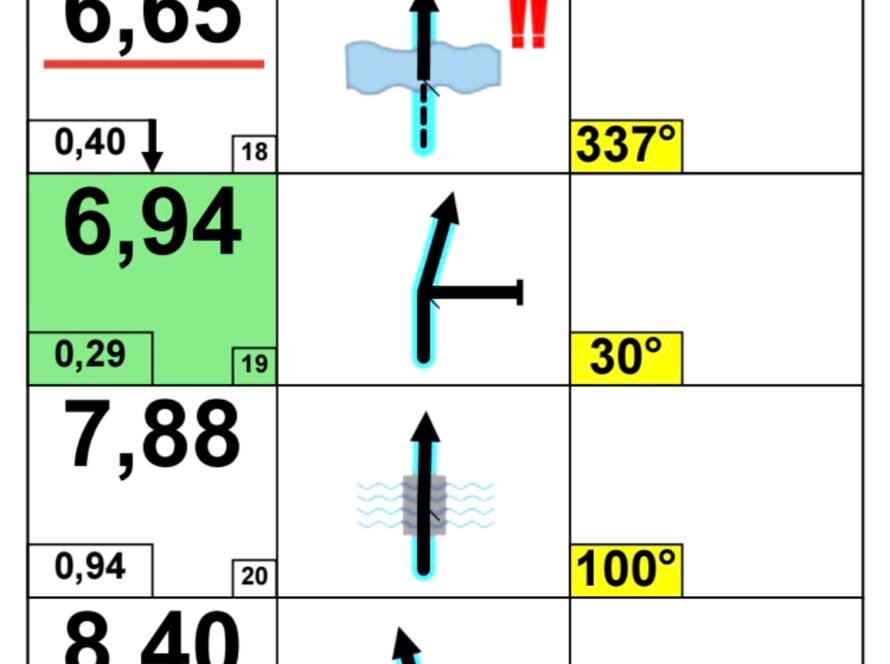

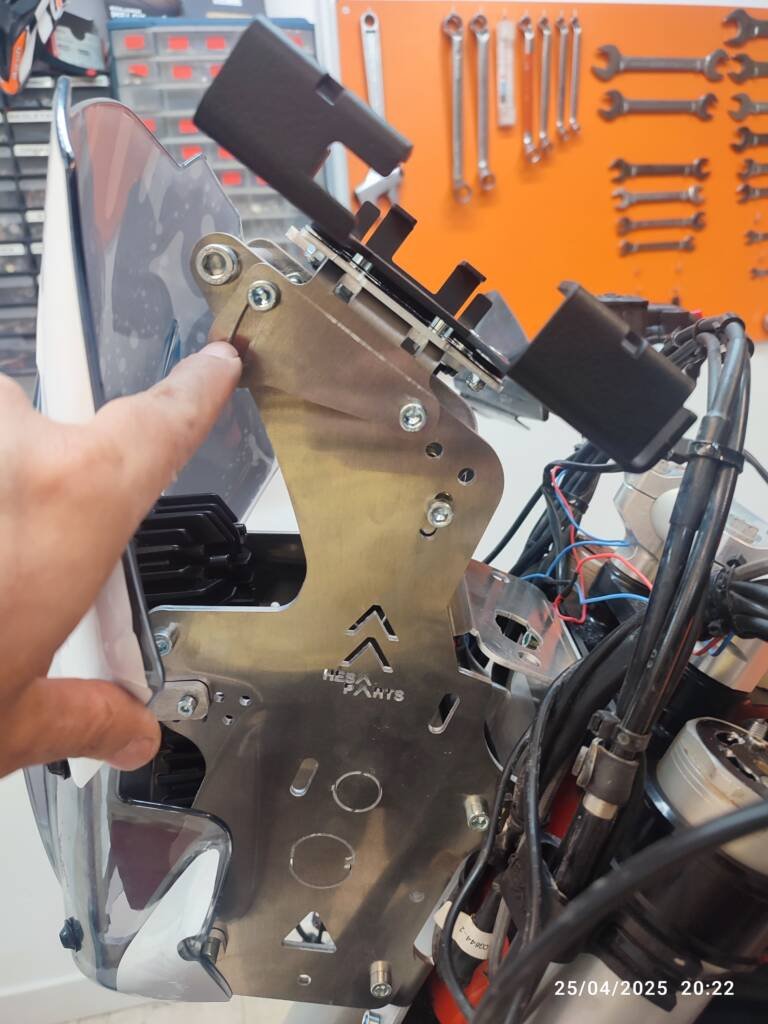

After several prototypes, we’ve just fine-tuned the tower’s height so the navigation equipment sits at the desired height, covered by the screen, with a good angle, an ideal position for the screen against the wind, and the ability to see the standard speedometer.

We’re not entirely satisfied with the result. The screen has a slightly raised shape with dangerous spikes if it hits with the helmet.

We decided to continue searching and found several candidates. We were obviously not the first to conduct a search in the Chinese market, and we concluded that there were only four screens that could be used for this project.

We already made the prototype for the first one, so it was ruled out.

The second model is for the YAMAHA T700,

the third is for the KAWASAKI Z900,

and the fourth is for a Honda scooter.

We opted for the third model for the simple reason that it has a thick edge on the screen, which we like to avoid cuts and accidents in the event of a fall.

The screen in question costs only €15, so that’s great! We’ll be able to keep the costs of our project down.

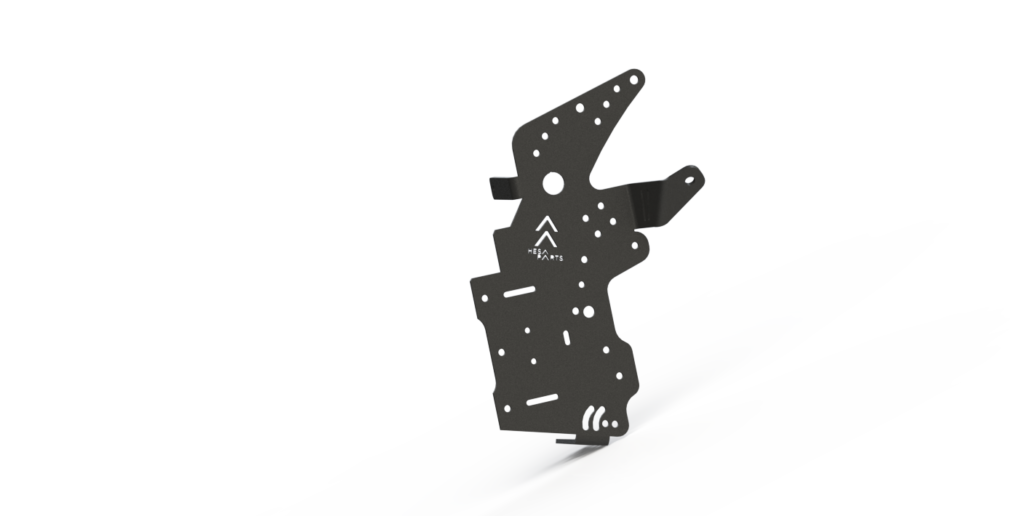

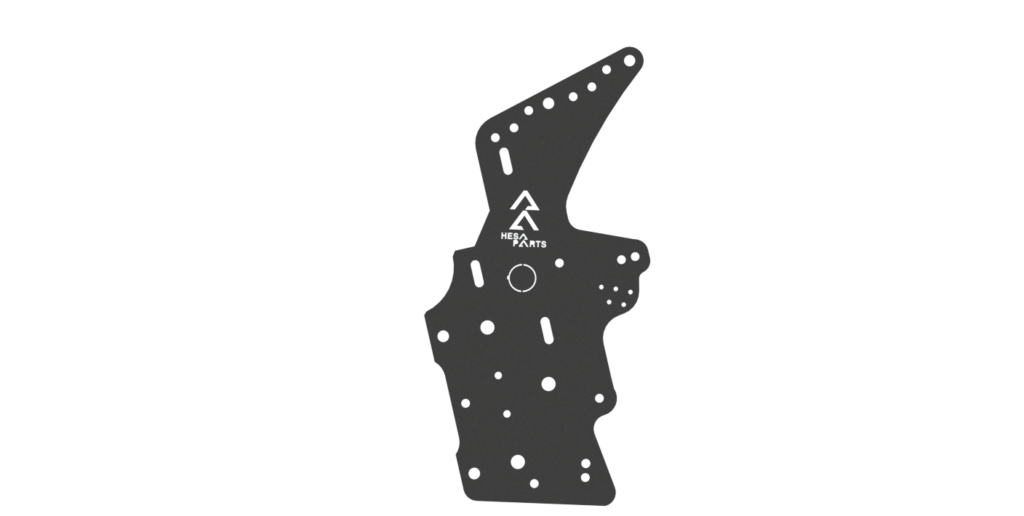

Since we have the main measurements of the tower already designed, let’s see how we fit that dome into our tower… so we decided first of all to design the anchorage

From here, the design came together smoothly. We worked hard on our first prototype, looking for solutions and taking measurements, so now the design is flowing easily.

We created our own template for the stickers, and they accuse us of copying them… Did they expect us to put the stickers over the lights? The screen size doesn’t allow for much more.

This is how we work. No 3D scanners… entirely designed in our design department. Prototyping entirely in our printing department. Assembly and development entirely in our workshop. All made and assembled in Europe.

This is HESAPARTS from the inside out, and this is how we work. We’re very proud of not depending on anyone and being able to fully determine the direction of the company. We work hard to be able to offer our customers the best of us

When the competition isn’t happy with us, it’s a sign we’re doing well. And we can assure you that learning and the desire to improve can only lead to doing better every day.

We’re not makers who replicate parts on a printer, nor do we photograph parts for sale, We’re not create spectacular social media. We’re designers, mechanics, bikers… ordinary people doing what they do best